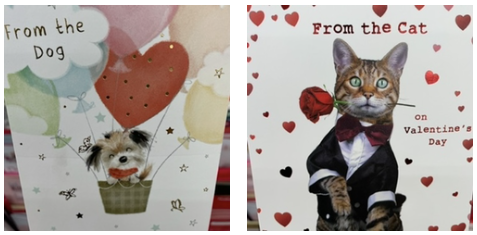

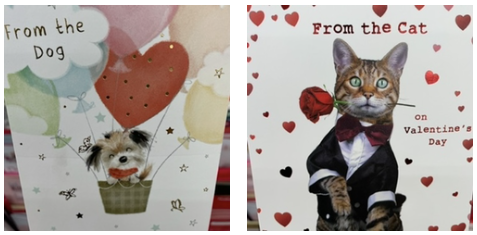

Where there is the traditional approach to Valentine’s Day in the newsagency of celebrating love, there is also the opportunity of having fun. The Valentine’s Day cards from the dog and from the cat cards are one example of this opportunity – these cards offer retailers an opportunity to subtly poke fun at the day, for us to not take ourselves too seriously.

Big retailers, of course, are all in, at one high-volume level, with front of store displays and, primarily, focussed on cliche items like chocolates, cheap plush sold at a premium price, flowers and cards. By playing with the quirky and at the fringe, I think we have an opportunity to stand out.

That’s what we are doing. Through some social media posts and in other ways, we are pitching an alternative, fun Valentine’s Day. Okay, we offer the traditional cards and are pitching them – but even there we are trying to be less commercial and more 2022 in the pitch. We really don’t want to get lost or unnoticed in the big retailer Valentine’s Day noise as that’s a cacophony that local retailers are less likely to win from.

I like the dog and cat card because they are niche and quirky, because they give us permission for some fun. So, that’s what’s we have been doing already on socials and in-store.

The more we play outside what is expected the more we are likely to be remembered. This is vital for our local retail businesses … and, seasons like Valentine’s Day provide is the perfect platform on which to speak to outpoints of difference, without being too obvious.

For the more traditional, but still nuanced, pitch, here;’s what we have at the counter at one of our stores.

I say nuanced because of the card selection chosen for the counter.

And, here’s what we have for Valentines Day inside the shop door. This is in a shop serving primarily retirees.

That’s not it though. We are pitching Valentine’s Day in three different locations in-store, to make the most of the opportunities its and knowing that shoppers will pass a pitch twice before noticing it the third time.

Valentine’s Day offers a unique opportunity in 2022 to pitch something to distract from the messy and challenging Covid situation and the heightened poison of this being an election year in Australia. It’s a distraction, a welcome distraction. The dog and cat card are, to me, a perfect example of welcome distraction that we can play with.